In April 2019. Our company cooperation with the Nanyang power plant. Before that according to the customer's detailed requirements, we built a technical team in order to satisfied customer's technology requests for performance, structure, design, function, and installation offer the best solution. Finally, in May, we start to manufacture the 130t/32t-span 28.5m European double girder overhead crane.

Main hook: 130t, normal lifting speed 1.6m/min

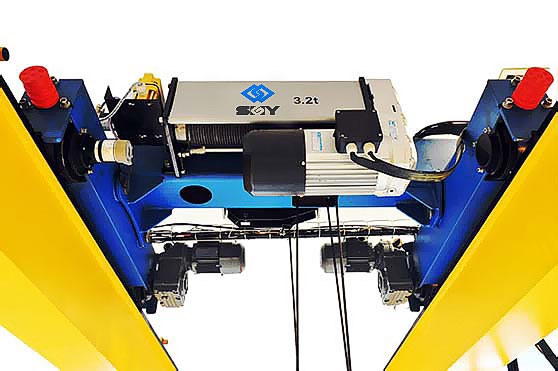

Auxiliary hook: normal is 8.0m/min

Trolley traveling: normal 20m / min

Crane traveling: normal 30m/min

When the main and auxiliary hooks are continuously adjusted, the ratio of the continuous minimum frequency adjustment speed to the maximum frequency adjustment speed is about 1:15.

When the large and small cars are continuously adjusted, the ratio of the continuous minimum frequency adjustment speed to the maximum frequency adjustment speed is about 1:25.

There is a walkway outside the main beam, surrounded by protective railings (1.2 meters in height) and foot guards (performed according to GB4053.3<<Fixed Industrial Protective Railings). The driver's cab is located on the side of the A row (tentatively), and the outside has a double armrest inclined ladder leading to the walkway.

The welding form and size shall comply with the provisions of GB324-2008 "welding code" and GB986-88 "Basic form and size of manual arc welding joint". Parts that require on-site welding are welded on-site by the seller and provide welding inspection methods.

The materials of the bridge, trolley, hook, and accessories should be reasonably selected. The bridge structure adopts Q345-B or better materials so that it can meet the operation under various conditions. The material limit requirements are not less than the standards listed in clause 4.6. All materials should have a quality guarantee, test report, inspection record and certificate of conformity, otherwise, they should not be used.