Overhead crane is a bridge-type crane, which is widely used in indoor and outdoor warehouses, workshops, docks and open-air storage yards. The following is the safety inspection and maintenance of bridge cranes.

Overhead crane safety inspection matters

1. Lifting limit stop, stroke limit switch and interlocking mechanism are normal, safe and reliable.

2. The main parts meet the safety requirements: the opening enlargement is less than 15% of the original size, and the torsional deformation is less than 10%; the plate hook bushing wear is less than 50%, the plate hook mandrel wear is less than 5%, no peeling, Burr, welding repair. There are no obvious defects in the hook hanger and pulley.

The amount of wire wear and corrosion on the surface of the wire rope is less than 40% of the diameter of the wire. Broken wires are less than 10% of the total number of wires in a twist distance. , Annealing, burn-out phenomenon.

The ends of the steel wire rope are connected and the clamps, pressure plates, and cymbals are connected intact, without looseness, no less than two pressure plates, and no less than three clamps. There is no crack in the drum, no looseness in connection and fixing; the drum wall wear is less than 20% of the original wall thickness; the safety coil is not less than 2 turns, and the diameter ratio of the drum to the wire rope meets the requirements.

The balance wheel is fixed intact, and the wire rope should meet the requirements. The brake has no cracks, no looseness, no serious wear, and the brake gap is of equal size on both sides, with sufficient braking force, and the brake belt wear is less than 50% of the original thickness.

Through the routine safety inspection of bridge cranes, it has played a significant role in preventing personal accidents, reducing equipment accidents, increasing equipment operating rates, and reducing maintenance costs.

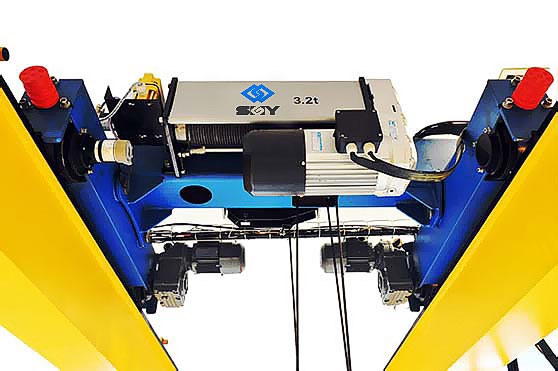

Bridge crane maintenance matters

1. Appearance of bridge crane: comprehensively clean the appearance to ensure no dust accumulation and no yellow robe. Check for cracks and welding.

2. Big and small cars: ① Check and tighten the drive shaft seat, gear box, coupling, shaft and keys for looseness; ② Check and adjust the brake wheel clearance to make it uniform, sensitive and reliable.

3. Check the reducer of the bridge crane mainly to see if it has oil leakage. There is an abnormal sound inside the box during operation, it is necessary to open the box cover for inspection. Generally it is caused by bearing damage, excessive backlash of gear meshing, serious tooth surface wear and other reasons.

4. Lifting and hoisting: ① Check whether the steel wire rope, hook and pulley are safe and reliable. If the wear exceeds the specified value, it should be replaced. ② Check and adjust the brake to make it safe, sensitive and reliable.

5. Inspection of bridge crane wire rope. Commonly used varieties are phosphate-coated steel wire rope, galvanized steel wire rope and smooth steel wire rope. Inspection of wire ropes should focus on observing broken wires, abrasion, kinks, and corrosion. For some places where the wear and broken wires are more serious but have not exceeded the standard, do Mark for easy follow-up review. Attention should be paid to check whether the safety limiter of the wire rope in the drum is effective, whether the wire rope pressing plate on the drum is pressed tightly and whether the number of pressing plates is appropriate.

6. Lubrication: Check the oil quality and quantity of all parts, and add or replace lubricating oil as required.

7. Inspection of pulleys of bridge crane. The focus is on whether the groove bottom wear exceeds the standard and whether there are cracks on the cast iron pulley. As for the balance wheel of the pulley block of the pitching mechanism, it does not move because of normal circumstances, and it is easy to be ignored. Therefore, it is necessary to check the rotation flexibility before installation, otherwise, the length and tension of the left and right steel wire ropes cannot be automatically adjusted by the balance wheel during installation, which makes it difficult and difficult to adjust the rope at high altitude.

The above is an introduction to the safety inspection and maintenance of overhead cranes. I hope everyone will understand the safety inspection and maintenance of overhead cranes and help you.