Product introduction

The crane is composed with Girder frame, Crane travel device, and the trolley with lifting and moving device. There are Pave the rail for the trolley move on the main girder. Assemble the moving table on the outside of the two main girder, one side is prepare for the assemble and maintenance the crane move device, another side is prepare for the assemble of the trolley conductor device. There are full field of view Cabin suspend under the main girder, there are joint control desk or single control box packed within the Cabin, assemble the sidelong ladder between the Cabin and moving table, The main girder joint with the two side end carriage which with the joint point in the middle.

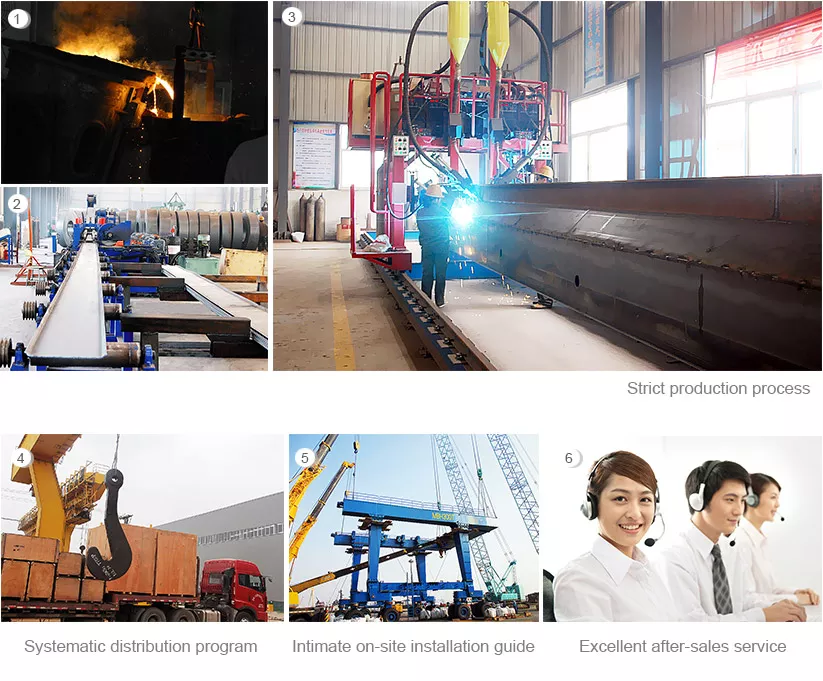

Crane girders

The crane girders are of welded girder construction. This result in lower dead weights with a high degree of vertical and horizontal rigidity and smaller wheel loads being transmitted to the crane runway.

Painting

In factory before manufacturing :

After manufacturing (after welding)

Average thickness : about 100 microns

Electrical elements

The crane that we are offering is designed to meet the required functions and requirement stated in your specifications, as well as for the operating conditions.

The sub-assemblies used by are standardized equipment of renowned manufactures and have been approved for specific crane operation by our test laboratory. Their characteristics regarding impact,vibrations, wear and safety were examined. A continuous high quality standard is ensured by series production and standardized sub-assemblies.

The electrical equipment is accommodated in robust steel plate control cubicles, on the crane girder.

Type of enclosure IP 55.

All movements can be switched off by actuating the emergency-off switch at the control station via a main contactor.

Power supply cable and control cable along the girder.

A protective earth conductor is fitted as standard. A crane switch is provided.

Travel end switches

Long and cross travel limited by means of preliminary and final limit switches

Overload protection

In the event of overload, the hoist unit switches off and only the lowering motion is possible.