|

apacity

|

Main

|

t

|

50

|

75

|

100

|

200

|

320

|

400

|

500

|

|

|

Aux

|

10

|

20

|

20

|

32

|

50

|

30

|

80

|

|||

|

Span

|

S(m)

|

30

|

35

|

40

|

16

|

22

|

18

|

18

|

28.5

|

|

|

Lifting height

|

Main

|

m

|

Above rail max.22

|

22

|

16

|

12

|

13

|

18

|

3 3/10

|

|

|

Aux

|

Above rail max.24

|

17.5

|

13

|

14

|

20.0

|

34.0

|

||||

|

Lifting speed

|

Main

|

m/min

|

7.68

|

6.25

|

4.62

|

0.2-1.8

|

0.14-1.4

|

0.15-1.5

|

0.15-1.5

|

|

|

Aux

|

19.8

|

9.28

|

9.28

|

6

|

7.5

|

6

|

0.6-6

|

|||

|

Trolley speed

|

m/min

|

38.6

|

38.9

|

13.1

|

20

|

7

|

10

|

1.36-13.6

|

||

|

Crane speed

|

m/min

|

42.7

|

17.8

|

16

|

17

|

18

|

1.6-16

|

|||

|

Work duty

|

|

A5

|

A5

|

A5

|

A5

|

A5

|

A5

|

A5

|

||

|

Track

|

|

QU 80

|

QU 100

|

QU 120

|

||||||

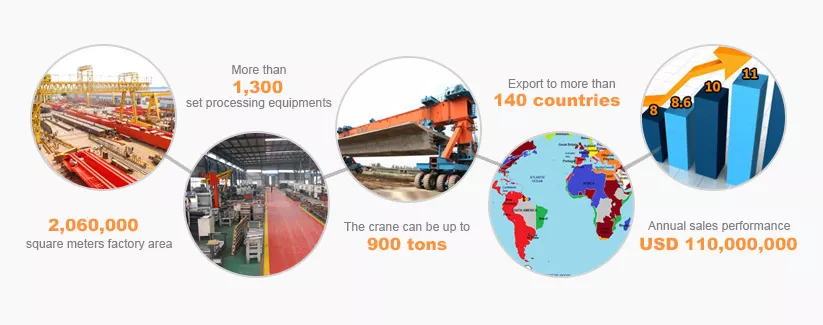

Establish strong sales service system with full coverage for 6 continents, 140 countries.

24 hours, 365 days, 1000+ technical professionals

Whatever your requirements, you 'll find the perfect service-oriented solution to match your

specific needs with our help.

Right where you need us,whenever you need us

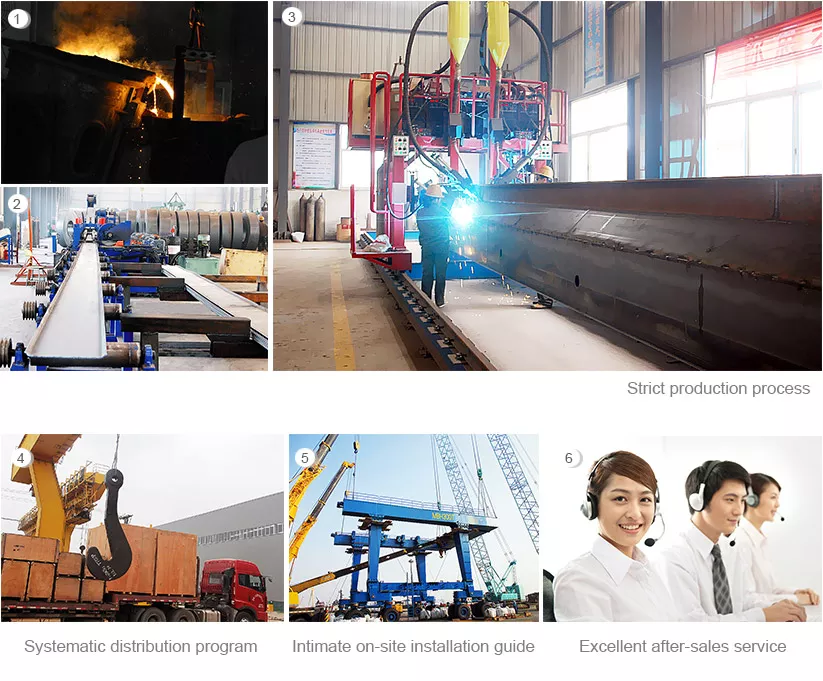

We have a strict production process,the systematic distribution program,intimate on-site installation guide,excellent after-sales service to ensure that the product show in your eyes completely at the first time and give you a comfortable trip of the crane procurement.

The price will be sent soon via email.

+86-13303807087