Gantry crane is a variant of bridge crane. It is mainly used for the loading and unloading of outdoor cargo yards, stockyards and bulk cargoes. Gantry cranes have the characteristics of high site utilization, large operating range, wide adaptability and strong versatility, and are widely used in port cargo yards.

Its metal structure is like a door-shaped frame, and two feet are installed under the main beam, which can walk directly on the track on the ground, and the two ends of the main beam can have outstretched cantilever beams.

Introduction

- What is a gantry crane

- Gantry crane classification

- What are the components of the gantry crane

- What are the display symbols of the gantry crane

- Working level of gantry crane

- Gantry crane operating procedures

- How to choose gantry crane

- Gantry crane maintenance

What is a gantry crane

The gantry crane is a bridge-type crane in which the bridge is supported on the ground track by the outriggers on both sides. Structurally, it consists of a gantry, a cart running mechanism, a hoisting trolley and electrical parts. Some gantry cranes only have outriggers on one side, and the other side is supported on the workshop or trestle, which is called a semi-gantry crane. The upper bridge frame of the gantry crane (including the main beam and the end beam), the outriggers, the lower beam and other parts are composed. In order to expand the working range of the crane, the main beam can extend beyond the outriggers to one or both sides to form a cantilever. A hoisting trolley with a jib can also be used to expand the crane's operating range through the pitch and rotation of the jib.

Gantry crane classification

Gantry cranes can be classified according to the structure of the door frame, the form of the main beam, the structure of the main beam, and the form of use.

Gantry crane door frame structure classification

Divided into gantry crane and cantilever gantry crane

1. Gantry crane

-

(1) Full gantry crane: the main beam has no overhang, and the trolley is carried within the main span;

-

(2) Semi-gantry crane: The outrigger has a height difference, which can be determined according to the civil engineering requirements of the site.

2.Cantilever Gantry Crane

-

(1) Double cantilever gantry crane: the most common structural form, the force of the structure and the effective use of the site area are reasonable.

-

(2) Single cantilever gantry crane: This structural form is often selected due to site constraints.

Gantry cranes are classified by the number of main beams

1. Single girder gantry crane

The single main girder gantry crane has a simple structure, is easy to manufacture and install, and has a small weight. The main girder is mostly an off-track box frame structure. Compared with the double main girder gantry crane, the overall stiffness is weaker. Therefore, when the lifting weight Q≤50t and the span S≤35m, this form can be adopted. Single main girder gantry crane gantry legs are available in two forms: L type and C type. The L-type is easy to manufacture and install, with good stress and low weight. However, the space for lifting goods through the outrigger is relatively small. The legs of the C-type are inclined or curved in order to have a large lateral space so that the goods can pass through the legs smoothly.

2. Double girder gantry crane

The double main girder gantry crane has strong bearing capacity, large span, good overall stability and many varieties, but its own quality is larger than that of the single main girder gantry crane with the same lifting capacity, and the cost is also higher. According to the structure of the main beam, it can be divided into two forms: box beam and truss. Generally, a box-shaped structure is used.

Gantry crane main beam structure classification

1. Truss beam gantry crane

The structural form welded by angle steel or I-beam has the advantages of low cost, light weight and good wind resistance. However, due to the large number of welding points and the defects of the truss itself, the truss beam also has the disadvantages of large deflection, low rigidity, relatively low reliability, and frequent inspection of welding points. It is suitable for venues with low safety requirements and small lifting capacity.

2. Box girder gantry crane

The steel plate is welded into a box-type structure, which has the characteristics of high safety and high rigidity. Generally used for large tonnage and super tonnage gantry cranes. As shown in the overview picture MGhz1200, with a lifting capacity of 1200 tons, is the largest gantry crane in China, and the main beam adopts a box girder structure. Box girder also has the disadvantages of high cost, heavy self-weight and poor wind resistance.

3. Honeycomb beam gantry crane

Generally refers to the "isosceles triangle honeycomb beam", the end face of the main beam is a triangle, there are honeycomb holes on both sides of the oblique belly, and there are chords on the upper and lower parts. Honeycomb beams absorb the characteristics of truss beams and box beams, and have greater stiffness, smaller deflection and higher reliability than truss beams. However, due to the use of steel plate welding, the self-weight and cost are also slightly higher than the truss beam. It is suitable for fields or beam fields that are frequently used or heavy lifting. Since this beam type is a patented product, there are few manufacturers.

Gantry crane use classification

1. Ordinary gantry crane

This kind of crane mostly adopts box type and truss type structure, which is the most widely used. It can handle various pieces and bulk materials, with a lifting capacity of less than 100 tons and a span of 4 to 39 meters. Ordinary gantry cranes with grabs work at a higher level. Ordinary gantry cranes mainly refer to hook, grab, electromagnetic and hoist gantry cranes, as well as semi-gantry cranes.

2. Hydropower station gantry crane

It is mainly used for hoisting and opening and closing gates, and can also be used for installation operations. The lifting capacity is 80-500 tons, the span is small, 8-16 meters, and the lifting speed is low, 1-5 meters per minute. Although this kind of crane is not often hoisted, once it is used, the work is very heavy, so the work level should be appropriately improved.

3. Shipbuilding gantry crane

It is used to assemble the hull on the slipway, and there are always two lifting trolleys: one has two main hooks, which run on the track of the upper flange of the bridge; the other has a main hook and an auxiliary hook, which are on the lower flange of the bridge. Runs on rails for flipping and hoisting large hull sections. The lifting weight is generally 100-1500 tons; the span is 185 meters; the lifting speed is 2-15 m/min, and the fretting speed is 0.1-0.5 m/min.

4. Container Gantry Crane

For container terminals. After the trailer truck transports the containers unloaded from the ship by the quay wall container carrier to the yard or the rear, the container gantry crane stacks them or directly loads them away, which can speed up the turnover of the container carrier or other cranes. The yard that can store containers with a height of 3 to 4 layers and a width of 6 rows is generally a tire type, and a rail type is also useful. Compared with the container straddle, the container gantry crane has a larger span and height on both sides of the gantry. In order to meet the transportation needs of the port terminal, this kind of crane has a higher working level. The lifting speed is 8-10 m/min; the span is determined according to the number of container rows that need to be spanned, the maximum is about 60 meters, corresponding to the lifting weight of 20-foot, 30-foot, and 40-foot long containers of about 20 tons and 25 tons, respectively. and 30 tons.

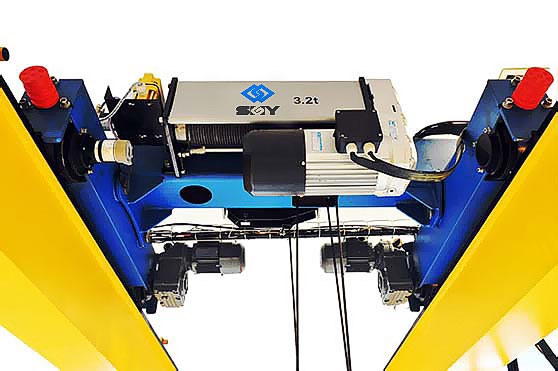

What are the components of the gantry crane

The gantry crane is mainly composed of the following components

1. Cylindrical wheel

2. Buffer

3. Block brake

4. Steel wire rope

5. Lifting hook

6. Driver's cab

7. Reducer

8. Casting pulley

9. Casting reel

10. Motor

11. Electronic control equipment

What are the display symbols of the gantry crane

1. Model standard gantry crane

The gantry crane is represented by the code, rated lifting mass, span, and working level.

2. Single girder gantry crane

Its symbols are: MDG, MDE, MDZ, MDN, MDP, MDS.

Such as: MDN - single main girder single trolley grab hook gantry crane;

MDS—single girder trolley three-purpose gantry crane.

3. Double girder gantry crane

Its symbols are: MG, ME, MZ, MC, MP, MS.

Such as: MG - double girder single trolley hook gantry crane;

ME—Double beam double trolley hook gantry crane.

Working level of gantry crane

Gantry crane is also the working level A of the gantry crane: it reflects the working characteristics of the crane in terms of load status and utilization.

The division of the working class is determined by the utilization class U and the load state Q of the crane. They are divided into eight levels from A1 to A8. Crane working level,

That is, the working level of the metal structure is determined according to the hoisting mechanism and is divided into A1-A8 levels.

Roughly equivalent to: A1-A4-light; A5-A6-medium; A7-heavy, A8-extremely heavy.

Gantry crane operating procedures

Operating procedures for double-girder bridge cranes

1. Before work

Check the brakes, hooks, wire ropes, safety devices and other components according to the requirements of the spot check card. If any abnormal phenomenon is found, it should be eliminated first.

The operator must confirm that there is no one on the platform or track before turning on the main power supply. When the power circuit breaker is locked or there is a notice board, the main power supply can only be closed after the original relevant person has removed it.

2. At work

When lifting heavy objects for the first time in each shift (or when the load reaches the maximum weight), the heavy objects should be put down again after being lifted 0.5 meters above the ground level, and the performance of the brakes should be checked.

During the operation, the operator should ring the alarm for the following operations according to the regulations.

-

(1) Lifting and lowering heavy objects; when driving large or small cars.

-

(2) When the crane is driving with unclear vision, it should continuously ring the alarm.

-

(3) When the crane approaches another crane in the span.

(4) When lifting heavy objects close to people.

The operation should be carried out according to the unified command signal.

When there is a sudden power failure during work, all controller handles should be placed in the "zero" position, and the crane should be checked for normal operation before restarting work.

During the normal operation of the crane and the trolley, it is strictly forbidden to turn on the reverse brake to stop; when changing the moving direction of the crane and the trolley, the handle must be placed in the "zero" position, so that the mechanism can be completely stopped before driving in the reverse direction.

For a crane with two hooks, when the main and auxiliary hooks are replaced and the heights of the two hooks are similar, the main and auxiliary hooks must be operated separately to avoid collision between the two hooks.

A crane with two hooks is not allowed to lift two objects at the same time; adjust the brake of the hoisting mechanism if it does not work.

It is not allowed to use the limit position limiter to stop, and it is strictly forbidden to adjust the brake of the hoisting mechanism under load.

Strictly implement the "ten do not hang" system:

-

(1) The command signal is unclear or the command is indiscriminate;

-

(2) Do not hang when the rated lifting capacity is exceeded;

-

(3) The use of the spreader is unreasonable or the objects are not tied tightly;

-

(4) Do not hang someone or other floating objects on the hanging object;

-

(5) The holding brake or other braking safety device fails to hang;

-

(6) Do not hang heavy objects on the road for direct processing;

-

(7) Changing and hanging without hanging;

-

(8) Do not hang explosive objects;

-

(9) Objects buried in the ground should not be lifted up;

-

(10) Objects with angular block mouths should not be hung without padding;

If any abnormality is found, stop the machine immediately, check the cause and eliminate it in time.

3. After work

Raise the hook to a certain height, park the cart and trolley at the designated position, and put the controller handle at the "zero" position; pull down the switch handle of the protection box to cut off the power supply.

Perform routine maintenance.

Do a good job of handover work.

Operating procedures for single girder overhead cranes

1. Before work

For single-girder overhead cranes with a cab, before the driver takes over to drive, the hooks, wire ropes, safety devices and other components should be checked according to the requirements of the spot check card, and any abnormal conditions should be eliminated.

For ground-operated single-girder bridge cranes, each shift should have a special person responsible for checking according to the requirements of the spot check card, and if any abnormality is found, it should be eliminated.

The operator must confirm that there is no one on the platform or track before turning on the main power supply. When the power circuit breaker is locked or there is a notice board, the main power supply can only be closed after the original relevant person removes it.

2. At work

When lifting heavy objects for the first time in each shift (or when the load reaches the maximum weight), the heavy objects should be put down again after being lifted 0.5 meters above the ground level, and the performance of the brakes should be checked.

Strictly implement the "ten do not hang" system:

-

(1) The command signal is unclear or the command is indiscriminate;

-

(2) Do not hang when the rated lifting capacity is exceeded;

-

(3) The use of the spreader is unreasonable or the objects are not tied tightly;

-

(4) Do not hang someone or other floating objects on the hanging object;

-

(5) The holding brake or other braking safety device fails to hang;

-

(6) Do not hang heavy objects on the road for direct processing;

-

(7) Changing and hanging without hanging;

-

(8) Do not hang explosive objects;

-

(9) Objects buried in the ground should not be hung;

-

(10) Objects with angular block mouths should not be hung without padding;

If any abnormality is found, stop the machine immediately, cut off the power supply, check the cause and eliminate it in time.

3. After work

Raise the hook to a certain height, park the cart at the designated position, and put the controller handle at the "zero" position; pull down the knife switch to cut off the power.

Perform routine maintenance.

Do a good job of handover work.

How to choose gantry crane

1. Selection of gantry crane

Under normal circumstances, the lifting capacity is less than 50t, the span is less than 35m, and there are no special requirements for use, the single main beam type should be selected. If the width of the gantry leg is required to be large, the working speed is high, or the heavy and long pieces are often lifted, the double-girder gantry crane should be selected.

2. Span and cantilever length

The span of the gantry crane is an important factor affecting the quality of the crane itself. In the selection, the span should be minimized under the premise of meeting the equipment use conditions and meeting the span series standards.

3. The principle of determining the wheelbase

It can meet the stability requirements of the gantry along the direction of the crane track;

The overall dimensions of the goods should be able to smoothly pass through the flat steel frame of the outriggers;

Note that the wheelbase B is proportional to the span S. Generally, the wheelbase B=(1/4-1/6)S.

4. The gantry crane spacing size is determined

During work, there should be a certain amount of space between the external dimensions of the gantry crane and the passage of goods and transport vehicles in the yard to facilitate loading and unloading operations. When loading and unloading within the span, the general transport vehicle should keep a distance of more than 0.7m from the door leg. When the spreader is not working, there should be a distance of more than 0.5m from the transport vehicle, and when the goods pass through the door legs, there should be a distance of more than 0.5m.

Gantry crane maintenance

1. Lubrication

The working performance and life of each mechanism of the crane depend to a large extent on lubrication.

When lubricating, refer to its own manual for maintenance and lubrication of mechanical and electrical products. Grease should be injected once a week for traveling carts and hoisting trolleys. The hoist is filled with industrial gear oil, and the oil level should be checked frequently and replenished in time.

2. Steel wire rope

Pay attention to the broken wire of the wire rope. If there are broken wires, broken strands or the amount of wear reaches the scrapping standard, new ropes should be replaced in time. The steel wire ropes that can be used include phosphating coated steel wire ropes, galvanized steel wire ropes and smooth steel wire ropes.

3. Spreader

Spreaders must be checked regularly.

Four, pulley group

Mainly check the wear of the rope groove, whether the rim is cracked and whether the pulley is stuck on the shaft.

5. Wheels

Regularly check the rim and tread, and replace a new wheel when the rim portion is worn or cracked to 10% of its thickness.

When the difference between the diameters of the two driving wheels on the tread exceeds D/600, or there are serious scars on the tread, the car should be re-polished.

6. Brake

It should be checked once per shift.

The brake should act accurately, and the pin should not be stuck. The brake shoe should fit the brake wheel correctly, and the brake shoe clearance should be equal when the brake is released

Seven, reducer oil leakage reasons and preventive measures

There are three common reasons for oil leakage of reducer:

-

(1) Due to the unreasonable design of the manufacturer: in the design process, there is no special ventilation hole or the ventilation hole is too small and other design defects will cause the pressure inside and outside the reducer to be unbalanced and cause leakage failure, which will eventually lead to the leakage of the reducer lubricating oil. Fault. It is also possible that the connection surface of the reducer is not tightly sealed during long-term use, resulting in leakage.

-

(2) Due to the limited level of processing technology, the precision of the contact surface of the box is not enough, which leads to poor sealing performance and oil leakage.

-

(3) Due to improper maintenance by operators or maintenance personnel in the daily use process, many internal blockages are caused and the internal pressure is higher than the external pressure. At the same time, too much oil and the fasteners are not tightened, etc., which will cause the gap between the two boxes. The joint surface is not tight, etc., resulting in oil leakage.

In order to effectively prevent the oil leakage of the reducer, the manufacturer should improve the technological level and optimize the design scheme: a venting device can be added to the oil filler hole cover to ensure the balance and smoothness of the internal and external pressures. At the same time, in the design process, the process precision between the joint surfaces of the two boxes should be improved, so as to prevent the occurrence of oil leakage failure due to the lax contact surface. At the same time, it is necessary to do maintenance work in the process of daily use, and regularly check whether the ventilation holes, oil volume, box body, fasteners, etc. are in a normal state.