Portal crane is extensively applied to loading and unloading at port and materiel handing at shipyard and metallurgy industry. The main structure are steel frame. The lifting tools can be grab, container spreader, hook and electromagnet. This crane can be designed into stationary type and traveling type.

It can satisfy the high efficiency work requirement. With the advantage of heavy capability, high working efficiency, compact frame, calm movement, comfortable operation, safety and reliability, convenience maintenance, nice appearance and so on. It can make good use of the limited space of the port, yard and other places, and is available for empty and full loaded work of shipping and requirement of surface car transportation. And especially to general use port, it is a kind of hoisting machine with small investment and swiftness benefit for loading and unloading front apron container, sundries and bulk cargo.

High Quality Material and Components

The steel plates are all from Bao steel, Wuhan steel, Handan steel, all steel should be inspected by China National Technology Test Laboratory to ensure the quality.

The motor, gear box can be China top brand or International brand. The main electric unit can be Siemens, Schneider, ABB.

Modular Design

The component of crane are designed into various series standard modulars. And different modulars can be assembled to different products.

All the modular components can assembly and disassembly for good transportation.

Standard modular components can be manufactured with short producing time and steady quality. So that we can short the delivery time.

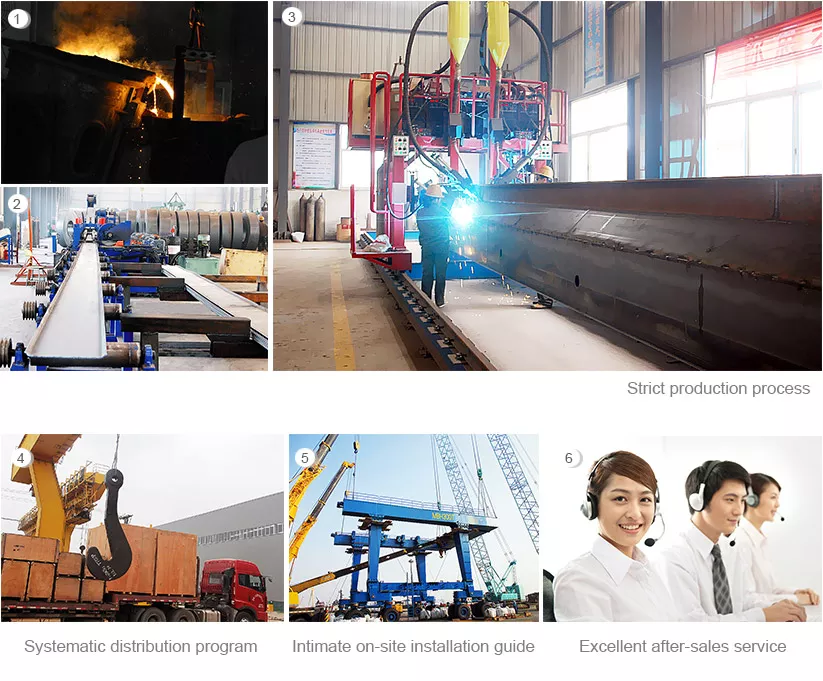

Advanced Manufacturing Technology

Pretreat

Both side of all the steel plates of crane are pretreated by pretreatment production line, Sand blasting-- Primer spray--Primer drying. Eliminate the inner stress of steel plate, increase the adhesive force of the steel structure. Ensure the appearance and anticorrosion quality.

Cutting

Steel plate cutting adopts whole sets Messer CNC plasma cutting machine from Germany, with very fast cutting speed, little deformation, High precision, Deviation could be controlled within 1mm, it can ensure the raw material at high quality standard and can reach top level in the industry.

Welding

The welding of main beam adopts high efficiency and intelligent welding robot, Weihua are No.1 enterprise who adopts this high technology machine. The welding joint inside of the main beam adapt advanced MAG welding, adapt Ar+CO2 mixed protective gas, The 4 welding joint outside of the main beam adopts automatic submerged-arc fillet welding machine. The welding of main beam adopts radiographic inspection and ultrasonic flaw detection for the welding joint and fillet weld position.

High Security

Overload limit monitor, it can shows the loading capacity and help the operator to avoid overload.

Automatic checking system, the controller can check the effectiveness of power voltage, the default Phase protection device and zero position of all buttons.

The driving and driven wheels have edge brake, and the brake interlocks with the electric to avoid crane from gliding so that can improve the safety.

| Product Specification |

1030 |

| Lifting Capacity |

t |

10 |

| Group Classification Of Complete Machines |

|

A7 |

| Lifting Height |

Above Rail Top |

m |

Grab 16 Hook 25 |

| Below Rail Top |

m |

Hook 15 |

| Working Radius |

Max. |

m |

30 |

| Min. |

m |

8.5 |

| Lifting Mechanism |

Group Classification |

|

M7 |

| Lifting Speed |

m/min |

60 |

| Luffing Mechanism |

Group Classification |

|

M6 |

| Luffing Speed |

m/min |

52 |

| Slewing Mechanism |

Group Classification |

|

M6 |

| Slewing Speed |

r/min |

1.51 |

| Traveling Mechanism |

Group Classification |

|

M4 |

| Traveling Speed |

m/min |

27 |

| Power Source |

|

3-phase A.C. 50Hz 380V |

| Track Gauge/Wheel Base |

m |

10.5/10.5 |

| Max.Slewing Radius |

m |

30 |

| Tail Slewing Radius |

m |

~7.8 |

| In-service Maximum Wind Pressure |

N/m |

250 |

| Out of-service Maximum Wind Pressure |

N/m |

1000 |

| In-service Maximum Wheel Pressure |

KN |

220 |

| Steel Track Recommended |

|

P50 |

| Installed Capacity |

kw |

350 |

| Product Specification |

1633 |

| Lifting Capacity |

t |

Grab 16 Hook 16/25 |

| Group Classification Of Complete Machines |

|

A7 |

| Lifting Height |

Above Base Level |

m |

Grab 20 Hook 28 |

| Below Base Level |

m |

16 |

| Working Radius |

Max. |

m |

Grab 33 Hook 33/23 |

| Min. |

m |

9.5 |

| Lifting Mechanism |

Group Classification |

|

M7 |

| Lifting Speed |

m/min |

50 |

| Luffing Mechanism |

Group Classification |

|

M6 |

| Luffing Speed |

m/min |

50 |

| Slewing Mechanism |

Group Classification |

|

M6 |

| Slewing Speed |

r/min |

1.51 |

| Traveling Mechanism |

Group Classification |

|

M4 |

| Traveling Speed |

m/min |

25 |

| Power Source |

|

3-phase A.C. 50Hz 380V |

| Track Gauge/Wheel Base |

m |

10.5/10.5 |

| Max.Slewing Radius |

m |

33 |

| Tail Slewing Radius |

m |

~8.5 |

| In-service Maximum Wind Pressure |

N/m |

250 |

| Out of-service Maximum Wind Pressure |

N/m |

1000 |

| In-service Maximum Wheel Pressure |

KN |

250 |

| Steel Track Recommended |

|

P50 |

| Installed Capacity |

kw |

450 |

| Product Specification |

3055 |

| Group Classification Of Complete Machines |

|

A5 |

| Elevating Capacity |

Lifting Capacity |

t |

Main Hook |

Aux.Hook |

| 30 |

10 |

5 |

| Radius |

m |

15~17 |

15~50 |

19~55 |

| Lifting Height |

m |

50 |

50 |

| Working Radius |

Max. |

m |

55 |

50 |

| Min. |

m |

19 |

15 |

| Speed Of Mechanism |

Lifting Speed |

m/min |

10(20,<12t) |

20(40,<2t) |

| Luffing Speed |

m/min |

~10 |

| Slewing Speed |

r/min |

0.24 |

| Traveling Speed |

m/min |

30 |

| Power Source |

|

3-phase A.C. 50Hz 380V |

| Track Gauge/Wheel Base |

m |

10.5/12 |

| Clear Height Of Portal |

m |

~10 |

| Tail Slewing Radius |

m |

~15 |

| Rotary Disc Tail Slewing Radius |

m |

=12 |

| In-service Maximum Wind Pressure |

N/m |

250 |

| Out of-service Maximum Wind Pressure |

N/m |

1000 |

| In-service Maximum Wheel Pressure |

KN |

250 |

| Steel Track Recommended |

|

P50 |

| Installed Capacity |

kw |

220 |

| Product Specification |

4073 |

| Group Classification Of Complete Machines |

|

A4 |

| Elevating Capacity |

Lifting Capacity |

t |

40 |

27 |

22 |

16 |

10 |

| Radius |

m |

20~45 |

20~55 |

20~60 |

20~67 |

20~73 |

| Lifting Height |

m |

45 |

| Working Radius |

Max. |

m |

73 |

| Min. |

m |

20 |

| Speed Of Mechanism |

Lifting Speed |

m/min |

0.2~10 |

| Luffing Speed |

m/min |

0.2~10 |

| Slewing Speed |

r/min |

0.3 |

| Traveling Speed |

m/min |

30 |

| Power Source |

|

3-phase A.C. 50Hz 380V |

| Track Gauge/Wheel Base |

m |

10.5/14 |

| Clear Height Of Portal |

m |

8.06 |

| Rotary Disc Tail Slewing Radius |

m |

~9.4 |

| In-service Maximum Wind Pressure |

N/m |

250 |

| Out of-service Maximum Wind Pressure |

N/m |

1000 |

| In-service Maximum Wheel Pressure |

KN |

400 |

| Steel Track Recommended |

|

P50 |

| Installed Capacity |

kw |

350 |

| Product Specification |

3055 |

| Group Classification Of Complete Machines |

|

A5 |

| Elevating Capacity |

Lifting Capacity |

t |

Main Hook |

Aux.Hook |

| 120 |

40 |

20 |

| Radius |

m |

24~33 |

24~60 |

28~65 |

| Lifting Height |

m |

60 |

60 |

| Working Radius |

Max. |

m |

60 |

65 |

| Min. |

m |

24 |

28 |

| Speed Of Mechanism |

Lifting Speed |

m/min |

6(12,<48) |

15(30,<8) |

| Luffing Speed |

m/min |

~10 |

| Slewing Speed |

r/min |

0.24 |

| Traveling Speed |

m/min |

30 |

| Power Source |

|

3-phase A.C. 50Hz 380V |

| Track Gauge/Wheel Base |

m |

13/16 |

| Clear Height Of Portal |

m |

~13 |

| Tail Slewing Radius |

m |

~17 |

| Rotary Disc Tail Slewing Radius |

m |

≤15 |

| In-service Maximum Wind Pressure |

N/m |

250 |

| Out of-service Maximum Wind Pressure |

N/m |

1000 |

| In-service Maximum Wheel Pressure |

KN |

450 |

| Steel Track Recommended |

|

Qu50 |

| Installed Capacity |

kw |

220 |

| Product Specification |

G0515 |

| Group Classification Of Complete Machines |

|

A6 |

| Lifting Capacity |

t |

5 |

| Lifting Height |

Above Base Level |

m |

9 |

| Below Base Level |

m |

7.5 |

| Working Radius |

Max. |

m |

15 |

| Min. |

m |

6 |

| Speed of Mechanism |

Lifting Speed |

m/min |

25 |

| Luffing Speed |

m/min |

22 |

| Slewing Speed |

r/min |

1.36 |

| Power Source |

|

3-phase A.C. 50HZ 380V |

| Rotary Disc Tail Slewing Radius |

m |

=4 |

| Overall Productivity |

t/h |

≥150 |

| In-service Maximum Wind Pressure |

N/m |

250 |

| Out of-service Maximum Wind Pressure |

N/m |

1000 |

| Installed Capacity |

kw |

45 |